Enable the Industrial Internet of Things (IIoT) with CNCnetPDM: See and output data from highly diverse manufacturing devices in consistent, comparable form. Allow them to communicate with each other. Control them from within your applications. Eliminate the need for third-party drivers, additional hardware or modifications of these devices.

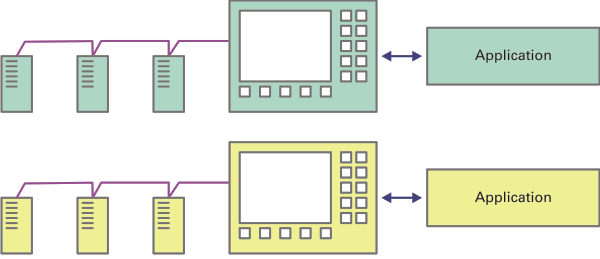

Lots of machines come with solutions that output their data to PCs or Smartphones and enable to control them. Because each manufacturer uses an own technique to do so this requires an own application for every device type. These applications neither output data in comparable form nor they are able to communicate with each other.

It may be possible to use a third-party driver that acquires, converts and outputs data in a standardized format. However, apart from the fact that this is usually prohibited this may influence functionality and lead to serious questions about warranty and service. Revovery or update of the device software usually removes these drivers.

FIG 1: Manufacturer specific solutions

- So, how can data from diverse devices be acquired and output in a consistent and comparable form?

- How can the necessity to buy and maintain and own solution for every type of device be avoided?

- How can devices from different manufacturers communicate with each other?

- How can be guaranteed that future devices can be integrated problem-free?.

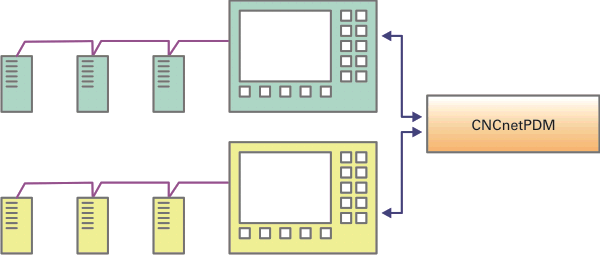

CNCnetPDM is based on a patent-pending method that allows you to directly access and utilize data of the manufacturers communication solution included with your device.

You can assign acquired values to consistent parameters which makes data from different sources comparable. The information is output in understandable form and can be processed in near real time by business solutions.

FIG 2: Functional principle of CNCnetPDM

CNCnetPDM's capability to convert standardized commands into instructions understandable by your device enables you to control your equipment.

Usage of pluggable, simply adaptable device drivers ensures problem-free integration of existing and future devices.

CNCnetPDM's proven high reliability and ease of use ensures the software can be installed quickly and operate flawlessly. [read more]